Extrusion Blow Molding

TECHNOLOGIES

What is Extrusion Blow Molding?

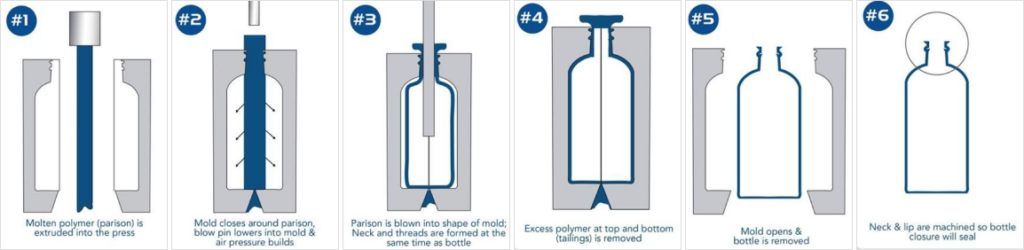

In extrusion blow molding (EBM), plastic is melted and extruded into a hollow tube called a “parison”. This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected.

What Are Typical Extrusion Qualities?

Common extrusion qualities include uniformity, consistent material thickness, efficient melt flow, minimal surface defects, and precise dimensional control.

Some other specific extrusion qualities include:

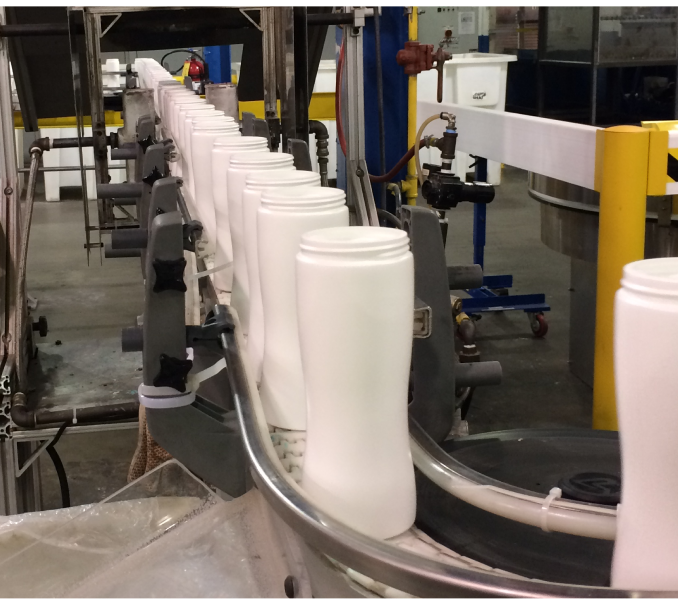

- Bottles & Jars: Healthcare OTC, Household & Industrial Chemical, Personal Care and Food ½ oz up to 2.5 gallon

Typical Resins: LDPE, HDPE, PP, and “soft touch” resins.

Standard Machinery: Bekum, Sabmann, Baker, Sig, R&B Plastics, B&W

Monolayer & multi-layer capable

Often multiple extruders for multiple bottle layers

TECHNOLOGIES

Silgan Plastics’ Extrusion Processes

We’re here to guide you through this fundamental process, from its basics to its wide-ranging applications across industries. With our expertise, you’ll gain a solid understanding of how extrusion shapes plastic production and how it can be harnessed to bring your innovative ideas to life.

EXTRUSION pROCESS

The Shuttle Machine

The most widely used machinery for blow molding HDPE and PP plastic containers globally is the shuttle machine. It is equipped with single or dual molds that shuttle or slide from beneath the die head to a blow pin station. These machines are available in various sizes and configurations, accommodating single-cavity to as many as 24-cavity designs, with bottle sizes ranging from ½ ounce to 2.5 gallons.

Shuttle capabilities:

- In Mold Labeling (IML)

View stripe on colored bottles

Handleware

Angled and offset necks

Retractable bases for deep pushups

Multiple necks

Dosing chambers

EXTRUSION PROCESS

BDS – “Blow Direct Screw”

Developed by Silgan Plastics, our unique, proprietary horizontal wheel technology revolutionizes blow molding. This innovative design streamlines mold transitions and blow pin positioning, showcasing our commitment to efficiency and precision.

BDS capabilities:

- ½ oz – ½ gallon bottles

Max height of a bottle is 13.8”. Max bottle diameter is 6.250” for rounds.

Max bottle width for ovals is 6.700”.

Non-flashed/non-handleware

Non-calibrated neck

Mono-layer or multi-layer (up to 3 layers)