Injection Molding

technologies

What is Injection Molding?

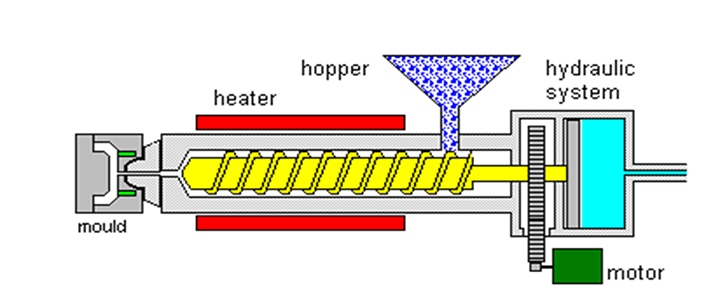

Injection molding is when melted or plasticized plastic material is injected into a mold where it is held until it is in a solid state, and then removed, duplicating the cavity of the mold. Resin enters the injection barrel from the hopper by gravity though the feed throat and heated to the appropriate melting temperature. If there are colorants, they are introduced either in a premixed state or separately through color feeders. The resin is then injected into the mold by a reciprocating screw. This process is the most economical method for mass-producing a single item.

The Injection Molding Process

The injection molding process involves injecting molten material into a mold cavity to create a desired shape. Once the material cools and solidifies, the mold is opened, and the finished product is ejected. This versatile method is widely used to manufacture a diverse range of plastic products, offering efficiency, precision, and the ability to create intricate designs with consistent quality.

What is Injection Molding Used For?

This technology is most commonly used to manufacture bottles, jars, and closures. The closures produced with this technology can be created both with and without child resistance.

Injection Molding can produce a two shot over-molded closure. This particular closure provides both an improved grip and overall product appeal in addition to eliminating the need for assembly.

Advantages and Disadvantages of Injection Molding

| ADVANTAGES |

| High production rates |

| High tolerances are repeatable |

| Wide range of materials can be used |

| Low labor costs |

| Minimal scrap losses |

| Little need to finish parts after molding |

| DISADVANTAGES |

| Higher equipment investment |

| Running costs may be high |

| Parts must be designed with molding consideration |