Injection Stretch Blow Molding

Why PET?

Here are some of the reasons why PET is the preferred material for plastic bottles and jars:

Crystal Clear – Glass-clear presentation of the product.

Pure – Products taste good. PET complies with international food contact regulations.

Safe – PET bottles are tough and virtually unbreakable during production, storage, and transportation. If they do fail, they split, not shatter. Their high impact and tensile strength make them ideal for carbonated products.

Good Barrier – The low permeability of PET to oxygen, carbon dioxide, and water means that it protects and maintains the integrity of products giving a good shelf life. PET also has good chemical resistance.

Lightweight – 10% weight of an equivalent glass pack, PET bottles reduce shipping costs by about 30%, and because the material in the wall is thinner, shelf utilization is improved by 25% on volume compared to glass. High-strength, low-weight PET bottles can be stacked as high as glass.

No Leakage – Absolute closure integrity is possible because of the injection molded neck finish. The absence of a weld line in the base means that PET bottles don’t leak.

Design Flexibility – Suitable for containers of all shapes, sizes, neck finishes, designs, and colors.

Recyclable – Excellent environmental profile due to single material. Used PET bottles can be washed, granulated into flakes, and reshaped as PET bottles or employed as material for strapping, carpeting, fiber filling, etc. PET is made from the same three elements (carbon, oxygen, and hydrogen) as paper, and contains no toxic substances. When burned, it produces carbon dioxide gas and water, leaving no toxic residues.

Long Shelf-life – Very good shelf-life performance.

TECHNOLOGIES

What is Injection Stretch Blow Molding?

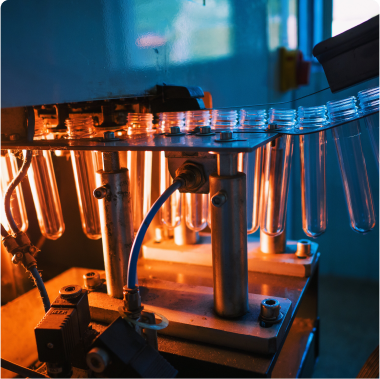

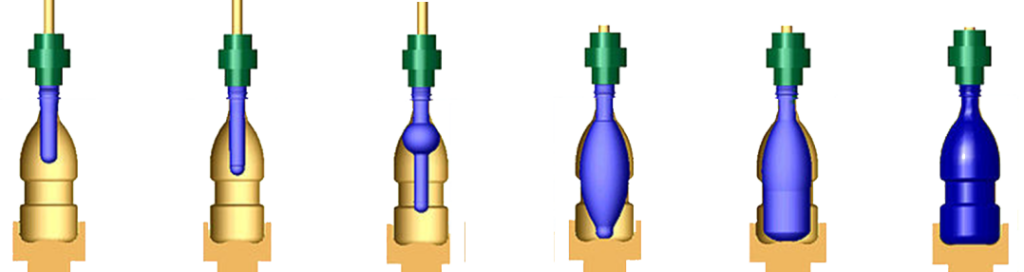

Injection Stretch Blow Molding (ISBM) is a specialized manufacturing process used to create hollow plastic containers. In ISBM, a preformed plastic injection-molded performs is heated and then stretched in a mold cavity before being blown into the final shape of the container.

This process combines injection molding and blow molding techniques, resulting in containers with precise dimensions, consistent wall thickness, and excellent clarity. ISBM is commonly used to produce bottles and containers for various industries, including packaged food, beverages, personal care, and pharmaceuticals.

PET & Stretch Blow Molding

PET bottles, with their lightweight clarity, are the packaging of choice for much of the food and personal care industry. Stretch blow molding is the common method for producing PET bottles.

Stretch blow molding can be a 1-Step or 2-Step process depending on the requirements of the package. The 2-Step process, similar to that of injection blow molding, begins with an injection molded perform. The preform then undergoes the stretch-and-blow process.

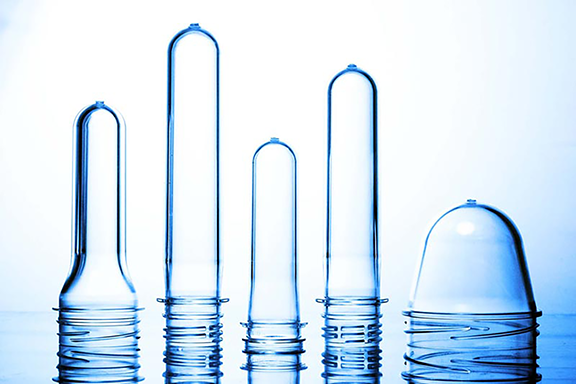

Preform Library

We have a complete range of stock PET preforms with varying weights, colors, and sizes for diverse applications that we can blow into your perfect package. Using state-of-the-art machines, we make preforms that are unmatched in finishing and performance.

Customizations are feasible – adjustments to existing tools can accommodate weight or finish variations. If you’re looking for a custom preform, reach out to us and we’ll be happy to assist.

***Please note: While we have stock preforms that can be blown into mold-available or custom bottles or jars, we do not sell preforms, themselves.