Plastic is a valuable material that has traditionally followed a linear model of “make, use, dispose”, resulting in large amounts being buried in landfills or worse, littering our environment. The model being adopted for the future is circular – cradle to cradle, not grave.

Spurred by the growing number of commitments by brands, retailers and other stakeholders to close the loop on plastics, the demand for recycled plastics is quickly increasing. Major CPGs and retailers have set ambitious goals to ensure all plastic packaging is reusable, recyclable or compostable. The problem: Demand for recycled plastics is rapidly outpacing supply. In the United States and Canada alone, today’s supply of post-consumer recycled plastics can meet only 6 percent of demand, which is projected to grow to as much as 7.5 million metric tons by 2030. That means plastics supply chains will need to shift from lines to loops.

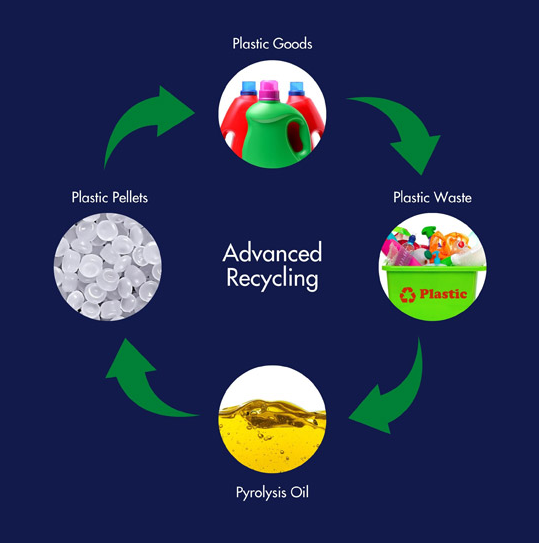

Advanced Recycling is an overarching term that covers many innovative processes such as chemical recycling, gasification or pyrolysis. The transformation can occur through a variety of processes, all of which avoid combustion, or burning, of plastics. These processes break down the polymer to the molecular level, making it comparable to the original virgin resin. As much as half of all global plastics packaging could be recycled by 2040 if these technologies were widely adopted.

Advanced recycling is pushing the boundaries of how and where recycled plastics can be used. Because it turns hard-to-recycle plastics into a reusable resource, it is a critical component to accelerating a circular economy that will help us achieve the goal of eliminating plastic waste from our environment. Advanced recycling technologies in use today can significantly increase the types and quantities of plastics we’re able to recycle. Unlike traditional recycling, advanced recycling can handle contamination, impurities, mixed polymers, and low-quality, low-density plastics.

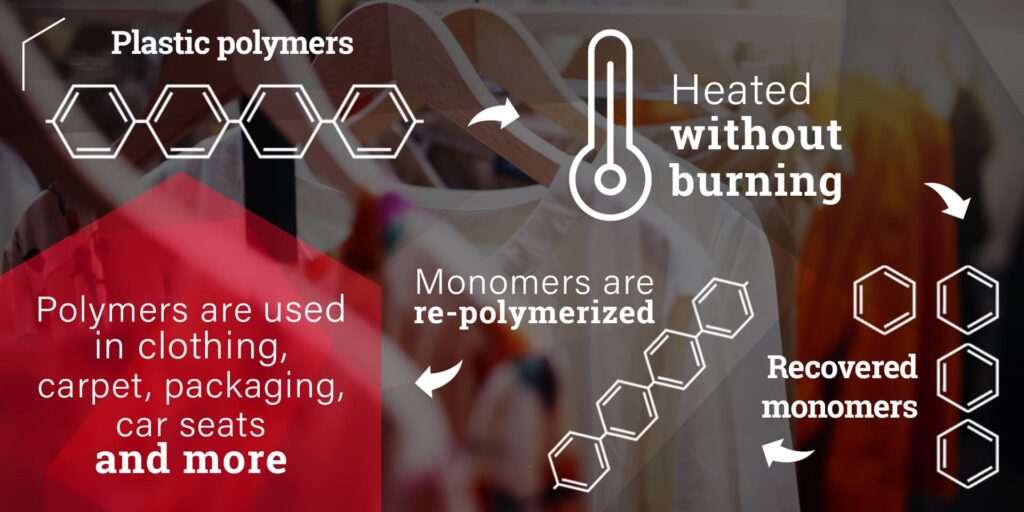

Chemical recycling is any process by which a polymer is chemically reduced to its original monomer form so that it can eventually be processed (re-polymerized) and remade into new plastic materials that go on to be new plastic products. Chemical recycling helps us overcome the limits of traditional recycling. It also helps manufacturers continue to push the boundaries of how, and where, recycled plastics can be used. Chemical recycling has long been used for nylons, and the industry is working to make it possible for other resin types.

Pyrolysis, sometimes called “plastics to fuel,” turns non-recycled plastics from municipal solid waste (garbage) into a synthetic crude oil that can be refined into diesel fuel, gasoline, heating oil or waxes. Using pyrolysis to convert non-recycled plastics into ultra-low sulfur diesel (ULSD) fuel reduces greenhouse gas emissions by 14% and water consumption by 58%, and it saves up to 96% in traditional energy use as opposed to ULSD from conventional crude oil.

Gasification turns non-recycled materials from municipal solid waste (garbage) into a synthesis gas, or “syngas,” which can be used for electric power generation or converted into fuel or chemical feedstocks, such as ethanol and methanol, some of which can also be used to make new plastics that go into consumer products.

Advanced recycling complements other plastic recycling options like mechanical, dissolution and organic recycling. Since it can deal with complex plastic waste streams, like films or laminates, chemical recycling can be used for plastic waste which would otherwise result in incineration or landfill. Because advanced recycling breaks down polymers into their building blocks, it also allows the production of recycled plastic with virgin plastic properties that can be used in demanding applications, such as food contact and pharmaceutical. With over 90% post-consumer plastic waste going to landfill and energy recovery in the US, there is a clear potential for improvement. Together, mechanical and chemical recycling can increase the overall recycling rates and contribute to a more circular economy for plastics.