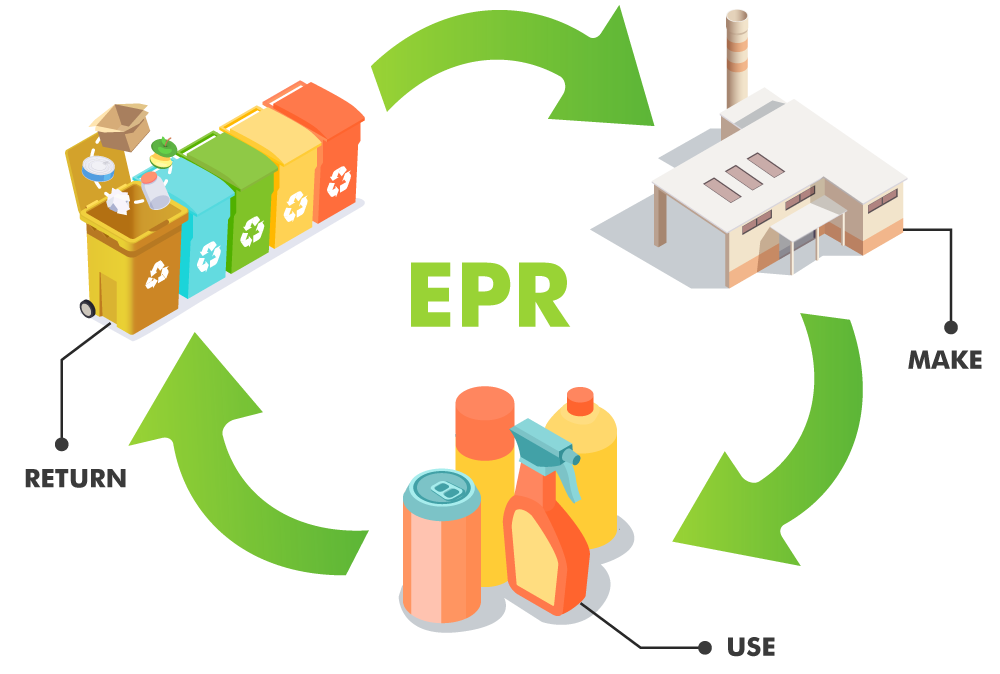

Faced with overwhelming amounts of waste that is currently being generated, many governments are implementing Extended Producer Responsibility (EPR) laws. EPR is a producer-focused mechanism that aims to reduce waste, particularly plastic waste, by increasing recycling and decreasing dependency on new raw materials. EPRs are a policy approach in which a producer’s responsibility, physical and/or financial, for a product is extended to the post-consumer stage of a product’s life cycle. Producers are required to provide funding and/or services that assist in recapturing their product after disposal in order to repurpose and minimize environmental impact.

EPR uses financial incentives to encourage manufacturers to design environmentally friendly products by holding producers responsible for the costs of managing their products at end of life. EPR is based on the principle that manufacturers (usually brand owners) have the greatest control over product design and marketing and have the greatest ability and responsibility to reduce toxicity and waste.

EPR may take the form of a reuse, buyback, or recycling program at the end of their life or by using a producer responsibility organization (PRO). A PRO is a third-party organization that collects and processes material. The PRO then distributes the funds to cover the costs required by program legislation. Costs generally provide funding for the end-of-life management of covered products (collection, sortation, processing). With a PRO, producers do not physically take back the product but instead support the process financially.

EPR policies and programs are well established in Europe, Canada, Japan, and South Korea for a wide range of products. Bills to create EPR programs for packaging in the United States have been introduced at the state and federal level. Many new bills and positions extend cost coverage to include outreach and education, infrastructure improvements, and end-market development for recycled materials. Organizations and policymakers are increasingly pointing to effective EPR as a necessary component of a comprehensive approach to addressing recycling challenges and concern over single-use product pollution.

Why Does EPR Matter?

If not managed correctly, plastic waste poses a critical threat to our environment. Considering the increased use of the material and its numerous applications, the amount of plastic waste has seen an exponential rise in the last couple of years. EPR is increasingly recognized worldwide as an efficient waste management policy to help improve recycling and reduce landfilling of products and materials. It’s therefore crucial for plastic producers and manufacturers to manage the collection and processing of the plastic waste they produce.

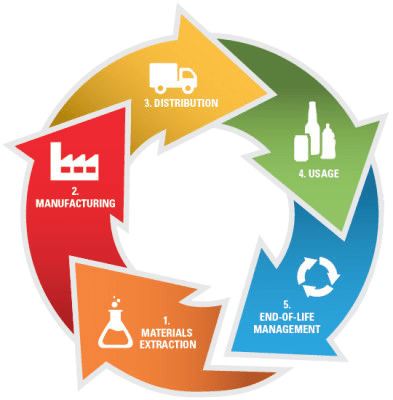

Rather than regulate disposal of products through traditional methods, extended producer responsibility is a preventive measure using a life-cycle or a “cradle-to-grave” perspective. Extended producer responsibility policies attempt to change how a product is produced—the “cradle”—to affect how a product may be disposed of—the “grave.”

The benefits of extended producer responsibility policies may be categorized as economic, environmental, and social. The cost for the management and coordination of the disposal of solid waste is most often the responsibility of local municipalities.

Rising levels of waste generation, more stringent technical requirements for the operation of landfills and incinerators, and increasing difficulty in constructing new waste disposal facilities due to public opposition all contribute to the growing cost of waste disposal. Extended producer responsibility is an attempt to provide an incentive to producers to design products with reduced environmental impacts while shifting the costs associated with disposal to the producer.

Environmental motivations for extended producer responsibility include increasing product recyclability, decreasing use of toxic components in products, and reducing the amount of material that is sent to a landfill or incinerator rather than reused or recycled. The recyclability of products is heavily dependent on product design. It is difficult to recycle products that are not designed for dismantling, have high levels of toxic ingredients, or have components such as composite resins that are problematic to recycle. With extended producer responsibility, designing products that can be easily recycled or reused is theoretically in the producer’s best interest because the producer is responsible for disposal. In addition to assigning responsibility for the disposal of products, most extended producer responsibility policies also require producers to recycle a specified percentage of the collected product by weight or volume.

Product recycling can reduce the amount of energy needed to manufacture a product and the creation of associated air and water pollution in comparison with producing a product from raw virgin materials. Finally, requiring producers to take responsibility for the disposal of products reduces the volume of material disposed of through incineration or in a landfill.

Extended producer responsibility also has social benefits. The implementation of extended producer responsibility policies may improve the public image of a company. Consumer demand for environmentally friendly products that can be recycled at end of life and manufactured with fewer toxic materials is increasing and EPR helps fuel the infrastructure to support this.